If you have disc brakes and you have to remove the caliper to get the disc off the spindle in order to get at the inner bearings, I think that you should inspect and pack them only under supervision at an auto class or under the eye of an experienced mechanic. It's not a difficult job; it's just that you may not get the calipers back on right, which could cause your brakes to malfunction. Otherwise, if you have drum brakes, go right ahead and do the job yourself. Figure 15-7 gives you a detailed look at what you'll encounter. Follow these steps to repack your wheel bearings:

- Take care if you have drum brakes and your bearings aren't sealed.

- If you haven't already done so, carefully slide the outer bearing, with the washer in front of it, off the spindle.

As you can see in Figure 15-7, the bearings are usually tapered roller bearings, not ball bearings.

- Take a good look at the grease in the spaces between the bearings. Don't wipe off the grease!

Caution: If the grease has sparkly silver slivers or particles in it, or if the rollers are pitted or chipped, you must replace the bearings. If the outer bearings are damaged, the inner bearings probably are, too. In this case, either replace the bearings in an auto class under the instructor's guidance or have a repair facility do the job for you.

- If you don't intend to repack your outer bearings at this time but you want to continue your inspection, don't attempt to wipe any grease off them, no matter how icky they look.

Just put them in a little plastic bag and lay them on your rag, pointing in the right direction. The bag will keep dust from getting into them. A speck of dust can wear out a bearing quickly.

If you do intend to repack your outer bearings, clean them thoroughly in solvent or kerosene with an old paintbrush. Don't smoke when cleaning the bearings!

You need to get rid of all the old grease in order to inspect the bearingsproperly. Also, when you repack the bearings with fresh grease, youdon't want any old grease spoiling the new stuff.

- When the bearings are shiny and clean, rinse them off with water and dry them, or use brake cleaner to remove the solvent.

Caution: If you pack new grease over the solvent, the grease will dissolve and you'll ruin your bearings.

- When the bearings are clean and dry, look at the rollers for signs of wear.

If the rollers are gouged or bluish in color, or if you can almost slip the rollers out of their place, replace the bearing and its race, which is pressed into the hub. You can see the race in Figure 15-7.

- To repack the outer bearing, take a gob of wheel-bearing grease (which is different from most chassis-lube grease) and place it in the palm of your left hand (if you're a righty).

Tip: You may want to invest in a pair of thin, disposable plastic gloves for this job. However, there's something kind of nice about fresh, clean grease, and if you use gloves, you miss one of the more sensual aspects of getting intimately involved with your car. In any event, hand cleaner gets the grease off easily.

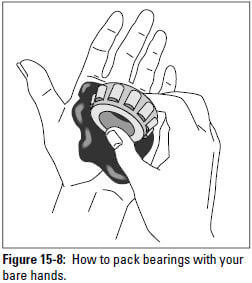

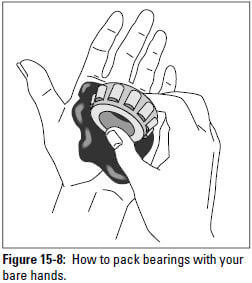

- Press the bearing into the gob of grease with the heel of your other hand (see Figure 15-8).

Another set of bearings is in the center hole of the drum or disc. These are your inner wheel bearings. At this time, you have to decide whether you're going to remove the inner bearings to check and pack them. The following will help you decide whether to remove the inner bearings:

- Caution: You can't remove the inner bearing from its seat in the hub unless you have a new grease seal for it. So if you're just checking on this occasion, leave the inner bearings alone until you're sure from the condition of the outer bearings that repacking is in order.

- Generally speaking, if the outer bearings look okay, the inner ones are okay, too. Just check each wheel and put everything back.

- Remember: If you're not planning to repack the inner bearings, do not attempt to take them out of their seat in the drum or disc. Skip Steps 10 through 13 and continue with Step 14.

If you are repacking the inner bearings, slide the brake drum or disc toward you, with the inner bearings still in place, but do not slide the drum completely off the spindle. Instead, screw the adjusting nut back in again, pull the drum toward you, and push it back.

The adjusting nut should catch the inner bearing and its grease seal and free them from inside the hub.

- Clean and pack the inner bearings using the technique described in Steps 5 through 8.

- Take a rag and wipe out the hole in the hub of the drum where the inner bearing was; then take a gob of grease and smooth it into the hole.

Caution: Be sure that the grease fills the races inside the hub where the bearing fits. Wipe off excess grease around the outside of the hole so that it doesn't fly around when the car's in motion, possibly damaging your brakes.

- Insert the inner bearing into the hub with the small end first. Take the new grease seal and spread a film of grease around the sealing end (the flat, smooth side).

- To fit the new grease seal into place properly, slide it in evenly;otherwise, it will bend or break and you'll lose your grease.

Tip: Find a hollow pipe or a large socket from a socket wrench set that has roughly the same diameter as the seal. With the flat, smooth side of the seal toward you, place the seal in the hub opening, and use the pipe or socket to move it into the hub gently and evenly. The new seal should end up flush with the outside of the hub or slightly inside it.

You'll be glad to know that your rear wheels have no wheel bearings to pack (unless your vehicle has front-wheel drive and the manual says that you can repack the rear bearings). You do have axle bearings, but you must replacethese if they wear out; you can't repack them.

Tip: If your vehicle is quite old and you hear a clicking or grinding noise from the vicinity of your rear wheels, have these bearings checked and replaced if necessary. It's easier to hear worn axle bearings when you drive down an alley or a narrow driveway because the noise echoes loudly.

From Auto Repair for Dummies, copyright © 2009 by Wiley Publishing, Inc., Indianapolis, Indiana. Used by arrangement with John Wiley & Sons, Inc.