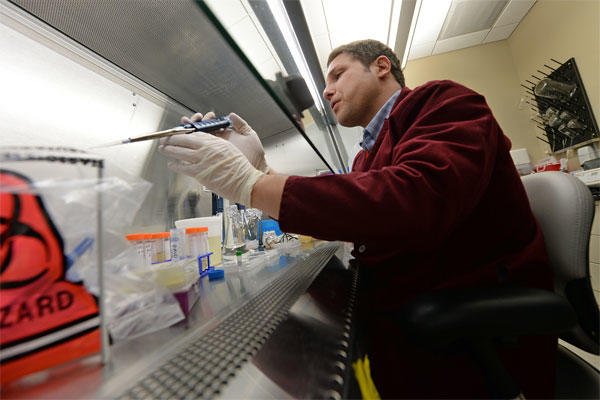

WASHINGTON – Within the laboratories of Naval Medical Research Unit-San Antonio, or NAMRU-SA, interdisciplinary teams of biomedical engineers, environmental microbiologists, dentists, chemists and other researchers work to research technology that will help wound treatment for the Defense Department warfighter.

NAMRU-SA’s mission is to conduct medical, craniofacial and biomedical research, which focuses on ways to enhance the health, safety, performance and operational readiness of Navy and Marine Corps personnel and addresses their emergent medical and dental problems in routine and combat operations. They share their findings with the other service branches.

Within NAMRU-SA, the Craniofacial Health and Restorative Medicine Directorate team focuses on research to re-engineer wound healing, infection control and dental treatments.

It also advances DoD’s environmental stewardship and assists wounded warriors.

“The research here encompasses everything above the shoulders,” said Navy Capt. Rita Simmons, NAMRU-SA’s commanding officer. “And the most common injuries now -- with the body armor being so effective -- we’re looking at wounds in the head and face area. That area of research has really moved to the forefront of our wounded warrior issues.

“Groups of scientists are spending a lot of time looking at ways to fight infection caused by injuries of various forms to the head, face and neck areas, and we are working to improve outcomes,” Simmons said.

Cranial Implants

The researchers at NAMRU-SA do not create the cranial implants, but they are working on redesigning the surface of titanium implants and developing nano delivery systems for antimicrobials and local anesthetics for controlling pain and infection after a burn or head injury, said Mauris DeSilva, a principle investigator with the directorate.

DeSilva said a patient who has a traumatic head injury may suffer the loss of portions of their skull bone or could have an elevation of intracranial pressure requiring the removal of a portion of the skull by surgeons to relieve pressure from excess fluid build-up. Replacing the skull bone often requires an implant. These implants are typically made of durable polymers or titanium. Patients who go through this surgery have a high rate of post-surgical infections, which may necessitate removal and replacement of the implant. Warfighters going through these surgeries could get post-surgical infections, which is what DeSilva’s team is trying to reduce.

“Obviously, through any type of force, whether it’s some sort of blunt force trauma or blast injury to the head, quite often, the skull will be damaged during that process,” Simmons said. “But there are ways to improve the cranial implants that are used as part of the recovery process and ways that we can help fight infection. We don’t make the implants here but we investigate new surface materials to improve the implant’s function and reduce the rates of infection that can directly improve quality of life outcomes after the injury.”

Simmons added, “Infections beget surgery and if there are more infections, there’s more surgery, lost tissue, lost recovery time, psychological impact.”

DeSilva said his team is working on optimizing the surface roughness of the implants. His team is also developing a nano coating that has nano materials with antimicrobials so they will have a controlled release over a specific duration of time.

“What we hope is, after recommending the roughness scale that’s optimized for this implant, we want to take it a step further and have the implant produce an acute antimicrobial release for at least 30 days,” he said. “This is the time period that they’re seeing is therapeutically effective to kill most infections.”

Wound Dressing

Currently, wound dressings used on the battlefield are traditional bandages, officials said. They help control hemorrhage but do not actively help in the healing process. Researchers are looking into creating bandages with bioactive factors such as growth factors, antibiotics and other agents that may speed up healing and reduce scar formation, said Navy Capt. Jonathan Stahl, a research dentist.

The engineers and scientists at NAMRU-SA have built an electrospinning device that researchers can use to make dressings using nanofiber technology. Biologically compatible natural and synthetic polymers are dissolved into a solvent along with bioactive agents and spun into a wound dressing using electrical forces. The resulting wound dressing will release the growth factors and other drugs over time and can be tested to determine if they improve and possibly accelerate the wound healing process. If successful, the new dressing may speed up healing and reduce scars for those injured on the battlefield.

Cracked Teeth

“Fractured teeth and restorations are the most commonly reported dental emergencies among military personnel,” said Navy Cmdr. David Leal, acting director for the Craniofacial and Restorative Medicine Department directorate. “This can be a showstopper for them, and it can affect their work schedules. If they’re deployed, they may have to get sent back home so somebody can take care of the problem.”

Current methods for detection of enamel cracks provide limited information, Leal said. For example, he said, trans-lumination uses a bright visible light, which scatters when reflected on enamel. The dentist can see the fracture but is unable to determine the depth or extent of it. X-rays are not very diagnostic unless the fracture is grossly displaced.

The researchers at NAMUR-SA designed the Optical Coherence Tomography, or OCT. It uses non-ionizing laser light for obtaining sub-surface images of translucent or opaque materials.

“Our team’s goal is to use OCT as a new tool to develop a predictive model that dentists can use chairside to quickly scan a tooth and help them to evaluate the severity of tooth cracks,” Leal said.

With OCT, the dentists will be able to obtain live 3-D images instantly, Leal said, that will aid them in making diagnostic decisions to assist them with appropriate treatment plans to prevent or reduce dental emergencies.

Nano Technology in Fillings

Navy researcher Dr. Amber Nagy, an environmental microbiologist and biomedical scientist, said one of the projects they are working on is improving resin formulations used to treat cavities. When a patient has a cavity cleaned out, he or she may receive an amalgam filling or a filling with resin that is tooth colored so that it is more aesthetically pleasing.

Nagy said the resin fillings will be modified to have nanoparticles in it, which can use visible light to activate antibacterial activity. The goal is to eventually issue each patient a toothbrush that has a light emitting diode in the toothbrush head so that every time he or she brushes his or her teeth, the resin antibacterial process will be activated by the toothbrush.

“We want to prevent bacteria from attaching to the tooth because bacteria are what cause the decomposition of the tooth or the decay of the tooth in the first place,” Nagy said. “By adding nano particles to the resin and hitting it with a light, it will prevent the bacteria from binding which will help to reduce cavity formation.”

Environmental Stewards

“All military installations want to be good stewards in the towns and cities in the states in which they live,” Simmons said. “Our goal and mission is to make sure our military dental treatment facilities properly handle and dispose of dental amalgam waste from fillings.”

A large number of cavities are filled with dental amalgam each year by Navy dentists to ensure sailors are ready for deployment, said Nagy, who’s the principal investigator for NAMRU-SA’s mercury abatement project. Dental amalgam is a safe, cost-effective, and durable metallic mixture consisting of about 50 percent liquid mercury and a powdered alloy that contains silver, tin, and copper. When mixed, the two components harden and become a solid material, commonly referred to as silver fillings, which is used to fill cavities in teeth.

“After dentists go in and drill to take out a filling, we don’t want the amalgam filling waste, which contains mercury, to go into the public wastewater stream,” Nagy said. “To combat this issue, we use a dental chair filter that was designed, developed, prototyped and patented by NAMRU-SA researchers for Navy dental chairs throughout the Navy and Marine Corps dental clinics. This novel filter can capture 96.7 percent of amalgam from dental wastewater before it enters the public wastewater stream, and it is inexpensive, easy to install, and available for use across all services.”

NAMRU-SA, the lead agent for mercury abatement, has patented and developed this chairside dental wastewater filtering system with a special focus on the accumulation of inorganic chemical contaminants such as mercury. The Navy is ahead of the Environmental Protection Agency proposed nationwide requirement that will mandate amalgam separators to reduce mercury and other chemical contaminants from dental wastewater in all dental facilities in the country, Nagy said.

“We’re ahead of the curve there, and we want to stay ahead of the curve and be the gold standard for environmental surveillance for all of the DoD,” Simmons said. She said this is a collaborative effort, and the Air Force is working with the Navy to help develop filter systems that also remove organic contaminants from dental wastewater.

Teamwork

Nagy said the success of the research could not happen without teamwork.

“This research isn’t possible without our interdisciplinary team,” she said. “We have an excellent, dedicated and diverse team working together to solve these problems to save lives out there in the field.”

Simmons said those interdisciplinary teams seek to address the problem by bringing together people with varying expertise to answer questions from many different approaches.

“This way, they can downscale to a more workable solution to tackle that problem from the onset, rather than taking that very serial approach of, ‘Well, we tried that and it didn’t work, now what am I going to do?’” Simmons explained.

She said the teams have been successful at developing synergistic cross-talk between departments and directorates with research.

“Teams come together to come up with the best solution in the fastest means possible,” Simmons said. “Whether it’s a device, a capability or a scientific innovation that can be pushed forward, NAMRU-SA continues to make great progress in research that optimizes warfighter readiness and saves lives.”