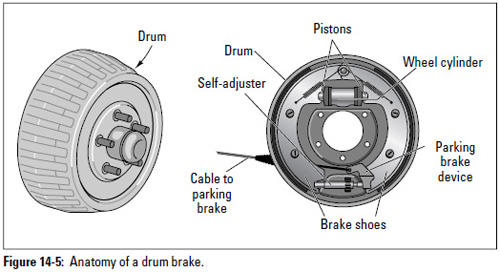

Drum brakes, shown in Figure 14-5, are the oldest type of brakes still on the road. Their main advantage is that they require less hydraulic pressure to stop your vehicle because the brake shoes tend to screw themselves into the brake drums after the pistons in the wheel cylinders push them there.

Tip: Even if your vehicle has disc brakes all around, you should read this section because they work on the same principles as drum brakes.

|

Brake Drums

Brake drums are hollow steel cylinders located in back of each wheel (refer to Figure 14-5). Because the lug bolts that go through them are the same as the ones that go through the wheels of your vehicle, the drums turn when the wheels turn. If you keep your brakes in good condition and replace your brake linings before they become too worn, your brake drums should last for the life of your vehicle. If drums become worn, they can be "reground" or "turned" to a smooth surface — unless they're worn more than their manufacturer's recommendation (usually more than .060 of an inch), in which case the drums must be replaced.

Wheel Cylinders

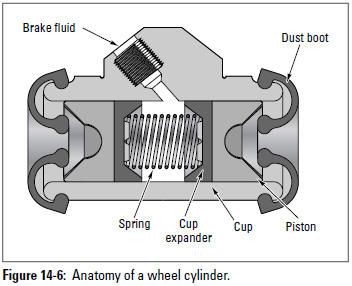

As you can see in Figure 14-6, wheel cylinders are small but powerful mechanismslocated inside each brake drum on the brake backing plate.

|

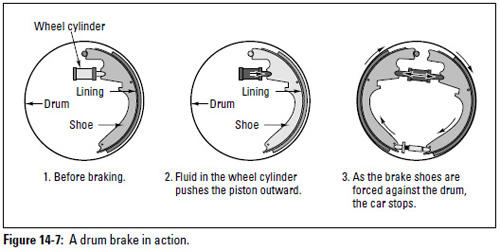

The brake fluid that's forced through the brake lines by the piston in the master cylinder goes into the wheel cylinders. The fluid then activates the two small pistons located inside each wheel cylinder by forcing them farther apart. The pistons emerge from either end of the wheel cylinder and push against the brake shoes. Figure 14-7 shows how the wheel cylinders work.

Car Smarts: Seals inside the wheel cylinder, called cups, keep the brake fluid from leaking out. Dust boots on each end of the wheel cylinder prevent dirt and dust from entering and fouling the cylinder.

|

Brake Shoes

As you can see in Figure 14-7, brake shoes are curved pieces of metal that stop the vehicle when the pistons in the wheel cylinders push them against the inside of the brake drum. The brake shoes are attached to a set of springs that draw them back into place when you take your foot off the brake pedal.

Brake Linings

Either bonded or riveted to the brake shoes are curved brake linings of tough, very heat-resistant material. As you can see in Figure 14-7, when the brake shoes are forced against the insides of the brake drum, the linings create friction, which causes the brake drum to stop turning. This in turnforces the wheels to stop turning, which stops the car.

Car Smarts: The brake linings on front-wheel drum brakes have a larger surface than those on the rear wheels because the front wheels bear most of the pressure of stopping (the weight shifts from the rear to the front when you brake). Also, in a front-wheel drive vehicle, most of the weight of the drive train is up front to begin with. For these reasons, on each set of brake linings on any wheel, the lining toward the front of the vehicle is larger and often is a different color so that mechanics don't make a mistake when replacing them.

Tip: You should check your brake linings for wear every 10,000 to 20,000 miles.

Adjusting Devices

Drum brakes that could be manually adjusted used to be popular, but today's passenger vehicles have self-adjusting brakes. The self-adjusting device is located at the bottom of the brake backing plate. These devices are used to adjust the distance between the surface of the brake lining and the inside of the brake drum when you step on the brake pedal. As your brake linings become worn, the distance increases, and the adjustment compensates for that. If you didn't have a self-adjusting device and your linings became very worn, eventually the brake shoes wouldn't contact the inside of the drum and your car wouldn't stop. You can see the self-adjusting device on the drum brake in Figure 14-5.

From Auto Repair for Dummies, copyright © 2009 by Wiley Publishing, Inc., Indianapolis, Indiana. Used by arrangement with John Wiley & Sons, Inc.